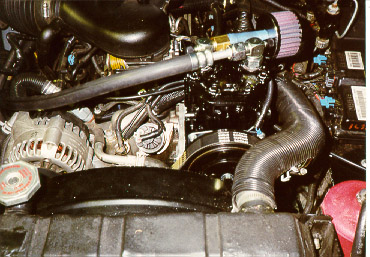

We initialy elected to take advantage of the internally lubricated Vortec A/C compressor to power an on-board compressed air system. The photo below shows the original assembly with the compressor with input and output lines modified to include a K&N filter on the input side and a high-pressure rubber hose (blue) connecting the compressor to a custom fabricated air block.

Unfortunately, like all vane-style compressors, the lubrication for the compressor must come from the refrigerant. When used as an air compressor, the unit is not sufficiently lubricated. We installed an in-line oiler (similar to those used to lubricate air tools) in the hope that would provide sufficient lubrication. It did not! The compressor lasted three years of very mild use before giving up the ghost.

The solution was to replace the vane-style compressor with a reciprocating-style (i.e,. piston and valve) compressor with an internal lubrication reservoir. We elected to switch to the classic upright York compressor. Specifically, we chose a 10 c.i.d. York compressor, capable of producing 4 CFM at 90 psi, operating at 1200 rpm. I found a low-cost ($40) unit from a 1983 Mustang in a salvage yard. This choice was based on the fact that it appears to be the only make and year of the upright York that came factory equipped with a serpentine clutch assembly. Although the clutch appeared to be in excellent condition, its electromagnet was positioned behind the actual pulley making the entire assembly very long -- in fact too long to mount on the Vortec. I ended up purchasing a new serpentine clutch assembly from Kilby Enterprises.

Mounting

of the York proved to be a bit of a challenge. As you can see from the

first photo in this chapter, there is not a lot room in the engine bay.

More importantly, with a serpentine-belt system, each belt-driven accessory

must be integrated with all others. Furthermore, the mounting bracket for

the stock A/C compressor is a large cast aluminum unit that also holds

the power steering pump. I basically had to modify the Vortec A/C

and PS bracket to accomodate the York compressor. This was done by cutting

and milling off the top of the stock bracket and then welding two upright

mounting plates to the stock bracket as shown in the photo to the right.

Alignment of the pulley requires that the rear of the compressor overlaps

with the front of the valve cover.

The

final assembly is shown in the photo to the left. Because the upright York

is a tall compressor (compared to the vane-style) and the mounting flanges

are on the top, clearance with the Cruiser's hood must also be considered.

The compressor cannot be raised too high over the valve cover without having

the input/output fittings hit the hood. Correct positioning and design

of the mounting bracket is thus critical. Indeed, the fit is very tight

in all dimensions. In fact, the small air cleaner almost prevents

closure of the hood. Even though I tried to accurately reposition

the center of the compressor drive shaft, the OEM serpentine belt was more

than an inch too short for the York. The new clutch is larger and I was

not able to set the unit as low as I wanted without hitting the valve cover.

BUT, IT FITS and works great!!

The

final assembly is shown in the photo to the left. Because the upright York

is a tall compressor (compared to the vane-style) and the mounting flanges

are on the top, clearance with the Cruiser's hood must also be considered.

The compressor cannot be raised too high over the valve cover without having

the input/output fittings hit the hood. Correct positioning and design

of the mounting bracket is thus critical. Indeed, the fit is very tight

in all dimensions. In fact, the small air cleaner almost prevents

closure of the hood. Even though I tried to accurately reposition

the center of the compressor drive shaft, the OEM serpentine belt was more

than an inch too short for the York. The new clutch is larger and I was

not able to set the unit as low as I wanted without hitting the valve cover.

BUT, IT FITS and works great!!

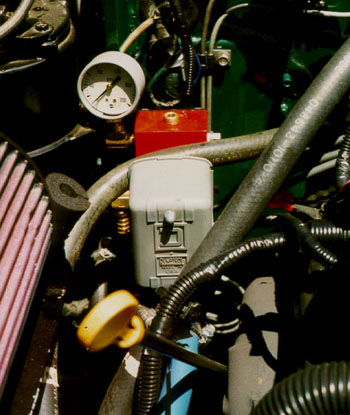

The

air block (red) is mounted on a bracket extending forward from the passenger's-side

firewall rib. It contains six NPT-threaded ports, including input,

output, pressure gauge, and three auxillary ports (two of which are planned

for future ARB locker connections). The input port is connected to

a pressure cut-off switch (grey). The Vortec compressor contains its own

high- and low-pressure switches which control (through the VCM and dash-mounted

air-request switch) operation of the A/C compressor clutch mechanism.

Unfortunately the stock A/C system was designed to operate at pressures

in excess (e.g., 200 psi) of those desired for a normal air compressor,

so a lower, high-pressure (adjustable) switch is required. The Vortec

high-pressure switch was therefore bypassed with a new circuit incorporating

the adjustable pressure switch on the air block.

The

air block (red) is mounted on a bracket extending forward from the passenger's-side

firewall rib. It contains six NPT-threaded ports, including input,

output, pressure gauge, and three auxillary ports (two of which are planned

for future ARB locker connections). The input port is connected to

a pressure cut-off switch (grey). The Vortec compressor contains its own

high- and low-pressure switches which control (through the VCM and dash-mounted

air-request switch) operation of the A/C compressor clutch mechanism.

Unfortunately the stock A/C system was designed to operate at pressures

in excess (e.g., 200 psi) of those desired for a normal air compressor,

so a lower, high-pressure (adjustable) switch is required. The Vortec

high-pressure switch was therefore bypassed with a new circuit incorporating

the adjustable pressure switch on the air block.

From

the air block, we installed a high-pressure rubber hose running along the

passenger's-side frame to a 3 gallon air tank tucked under the body just

fore of the rear frame crossmember/bumper. This tank is the type used on

semi truck/tractors for their air brake reservoir, and was obtained from

a salvage yard. It is shown in the photo below. The tank includes

a fitting for quick connection to an air hose to inflate tires or to operate

air tools.

From

the air block, we installed a high-pressure rubber hose running along the

passenger's-side frame to a 3 gallon air tank tucked under the body just

fore of the rear frame crossmember/bumper. This tank is the type used on

semi truck/tractors for their air brake reservoir, and was obtained from

a salvage yard. It is shown in the photo below. The tank includes

a fitting for quick connection to an air hose to inflate tires or to operate

air tools.