In

1992, General Motors and Dodge began equipping their trucks with a new

heavy-duty, 5-speed manual transmission known as the New Venture 4500,

or simply NV4500. This is a 5-speed, constant mesh transmission with

all forward gears fully synchronized (Dodge models even offer a synchronized

reverse gear, and that can be added to the GM versions). It is a

large and extremely sturdy transmission constructed with a cast iron case

and aluminum alloy top. It weighs in at just under 200 lbs (dry) and was

designed with the strength necessary for one-ton truck applications with

a GVW rating of 14,500 lbs. The 5th

gear is an overdrive with a gear ratio of 0.73:1. Immediately

upon its introduction, this transmission was recognized by off-road enthusiasts

to be an ideal transmission for conversions. In addition to its strength

and overdrive gear, it offered an ultra-low first gear ratio of 6.34.

Unfortunately, the ultra-low 1st

gear was discontinued in 1995 and replaced with a higher, but still-impressive

1st gear ratio of

5.61. To put these gear ratios in perspective the stock TLC 4-speed

has a 1st gear

ratio of 4.9:1. The early, low-gear-ratio transmissions

are obviously in high demand and with low supply (need I say expensive).

In

1992, General Motors and Dodge began equipping their trucks with a new

heavy-duty, 5-speed manual transmission known as the New Venture 4500,

or simply NV4500. This is a 5-speed, constant mesh transmission with

all forward gears fully synchronized (Dodge models even offer a synchronized

reverse gear, and that can be added to the GM versions). It is a

large and extremely sturdy transmission constructed with a cast iron case

and aluminum alloy top. It weighs in at just under 200 lbs (dry) and was

designed with the strength necessary for one-ton truck applications with

a GVW rating of 14,500 lbs. The 5th

gear is an overdrive with a gear ratio of 0.73:1. Immediately

upon its introduction, this transmission was recognized by off-road enthusiasts

to be an ideal transmission for conversions. In addition to its strength

and overdrive gear, it offered an ultra-low first gear ratio of 6.34.

Unfortunately, the ultra-low 1st

gear was discontinued in 1995 and replaced with a higher, but still-impressive

1st gear ratio of

5.61. To put these gear ratios in perspective the stock TLC 4-speed

has a 1st gear

ratio of 4.9:1. The early, low-gear-ratio transmissions

are obviously in high demand and with low supply (need I say expensive).

In weighing the options, availability and cost, we chose to purchase a 1995 model from a salvage yard. It came from a 3/4 ton Chevy 4WD that was rolled and totaled with slightly more than 15k miles on the odometer. It has the following gear ratios:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We compensated for the higher-geared NV4500 by trading

our '78, 4-speed, H42 transfer case for a 3-speed, J30 transfer case.

Our J30 is a '73 model, completely rebuilt by John Groves of Cruiser Parts

in Grants Pass, OR. Advantages of the J30 transfer case, relative to the

stock '78 (H42), include a low-gear ratio of 2.313 (relative to 1.959)

and an arguably stronger case. As shown in the following table, our

combination of '95 NV4500 and J30 Transfer case results in a final gear

ratio lower than that of the earlier-model NV mated to a stock '78 TC.

Our final ratio does not approach that of a Marlin Crawler, but is a significant

improvement over stock. The following table gives

some comparative final 4WD, low-range, gear ratios, including what we might

achieve by a future upgrade to 4.88 R&P gears.

|

|

Stock TC 4.11 R&P |

Stock TC 4.11 R&P |

Stock TC 4.11 R&P |

J30 TC 4.11 R&P |

J30 TC 4.88 R&P |

|

Ratio |

|

|

|

|

|

Installation

All adapters required to mate the NV4500 to the Vortec

engine and the TLC transfer case were purchased from Advanced

Adapters Inc. Vic Carrol at AA was especially helpful in selecting

the best components and in answering questions following the purchase.The

required parts for this conversion include the following:

The

NV4500 transmission requires modification before it can be mated to the

AA adapter assembly. Most, if not all, GM 4WD transmissions obtained

from a salvage yard will include the GM TC adapter housing, 8.125" in length.

Removal of this housing reveals the NV output shaft, overdrive gears and

a large (5"dia., 4" long) harmonic balancer. This balancer must be

removed. The recommended procedure is to purchase a GM SST socket

to remove the retaining nut. After learning of Mr. Goodwrench's price

for this special socket, I made one myself. Unfortunately, even with

my very heavy-duty socket and an enormous air impact wrench, I could not

budge the retaining nut. After hours of work wasted in building the

SST, I ended up taking 15 minutes and drilled two 1/4" diameter holes on

opposing sides of the nut and broke it with a chisel. This is definitely

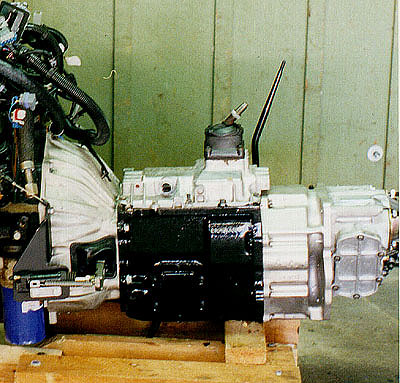

the easiest way to remove this balancer. The photo to the left shows

the NV4500 with the balancer removed. The threads between the two

splined sections of the output shaft are the ones threaded for the balancer-retaining

nut.

The

NV4500 transmission requires modification before it can be mated to the

AA adapter assembly. Most, if not all, GM 4WD transmissions obtained

from a salvage yard will include the GM TC adapter housing, 8.125" in length.

Removal of this housing reveals the NV output shaft, overdrive gears and

a large (5"dia., 4" long) harmonic balancer. This balancer must be

removed. The recommended procedure is to purchase a GM SST socket

to remove the retaining nut. After learning of Mr. Goodwrench's price

for this special socket, I made one myself. Unfortunately, even with

my very heavy-duty socket and an enormous air impact wrench, I could not

budge the retaining nut. After hours of work wasted in building the

SST, I ended up taking 15 minutes and drilled two 1/4" diameter holes on

opposing sides of the nut and broke it with a chisel. This is definitely

the easiest way to remove this balancer. The photo to the left shows

the NV4500 with the balancer removed. The threads between the two

splined sections of the output shaft are the ones threaded for the balancer-retaining

nut.

The

AA approach to mating the NV4500 to the TLC transfer case is accomplished

with a spud shaft that slips over the NV output shaft, extends through

the adapter housing and into the TC, becoming the input shaft for that

gear box. The NV4500 is a very long transmission, and in order to

reduce the total length of the complete assembly, the AA conversion requires

that the NV output shaft be cut off just aft of the foremost splines.

For this procedure, I used the steady hand of my understanding wife to

slowly turn the shaft while I cut with an air-powered cut-off disk.

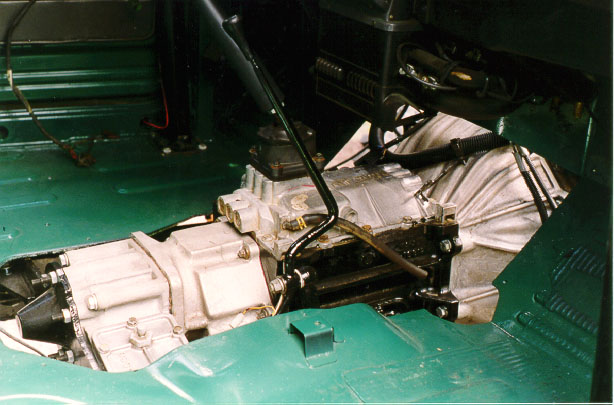

This photo shows the shaft after being cut at the AA-recommended length

of 4.5" from the rear of the transmission housing. AA also provides

the set collar shown, secured to the shaft with two allen bolts, to hold

the overdrive gears in proper position. The AA spud shaft mates with

the splines on the rear of the shaft in this photo. The gears and

shaft illustrated in this photo are lubricated by the main NV4500 synthetic

oil bath. The NV requires use of special GM or MOPAR

synthetic gear lube, and consequently an anerobic sealer must be used in

mating and sealing all components in contact with the lubricant.

The

AA approach to mating the NV4500 to the TLC transfer case is accomplished

with a spud shaft that slips over the NV output shaft, extends through

the adapter housing and into the TC, becoming the input shaft for that

gear box. The NV4500 is a very long transmission, and in order to

reduce the total length of the complete assembly, the AA conversion requires

that the NV output shaft be cut off just aft of the foremost splines.

For this procedure, I used the steady hand of my understanding wife to

slowly turn the shaft while I cut with an air-powered cut-off disk.

This photo shows the shaft after being cut at the AA-recommended length

of 4.5" from the rear of the transmission housing. AA also provides

the set collar shown, secured to the shaft with two allen bolts, to hold

the overdrive gears in proper position. The AA spud shaft mates with

the splines on the rear of the shaft in this photo. The gears and

shaft illustrated in this photo are lubricated by the main NV4500 synthetic

oil bath. The NV requires use of special GM or MOPAR

synthetic gear lube, and consequently an anerobic sealer must be used in

mating and sealing all components in contact with the lubricant.

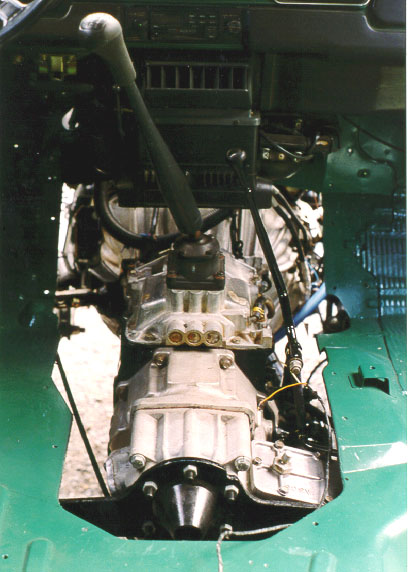

The above photo shows the bellhousing, NV4500, AA adapter and transfer case in their final position in the Cruiser. The NV shift tower sits well behind the heater and with its short throw is ideally located for optimal shifting. Note, however, that the AA transfer-case shift bracket results in the stock TC arm located about 2.5" aft of the NV shifter (and cowl hole). To overcome this mismatch, avoid elongating the TC hole in the cowl, and provide a longer TC shift lever, we fabricated a new and longer shift lever that includes a bent extension moving the lever forward.

Breather ports for the NV and transfer case have been plumbed into a 0.5" rubber line running to the top of the engine bay where they mate with similar lines from the two differential housings in a KNC breather filter assembly.

Finally, the photo below shows a view of the rear view of the NV assembly.

Cruise

Home For Additional Conversions and Features

|

Want info on how to JOIN this ring?? |

| [Prev] [Skip Next] [Random] [List Sites] [Next] |